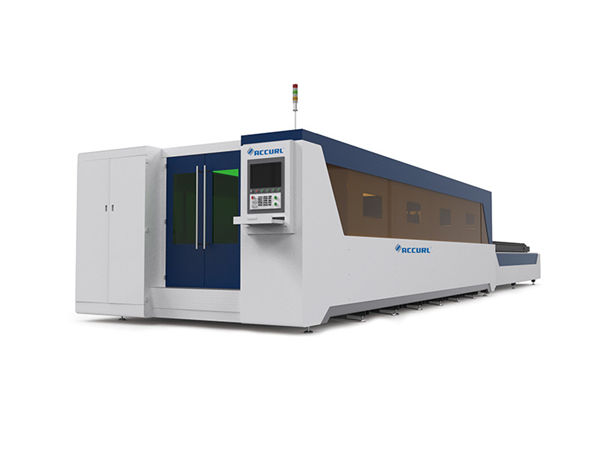

Ürün Detayları

Detaylı Ürün Açıklaması

| Ürün adı: | Metal Sac Lazer Kesici | Lazer Gücü: | 1000w 1500w |

|---|---|---|---|

| Lazer Dalga Boyu: | 1080nm | Çalışma alanı: | 3000 * 1500mm |

| Kesme Kalınlığı: | 0-16MM (Lazer Gücüne bağlıdır) | Güç kaynağı: | 380v |

| Garanti: | 1 yıl |

Product Desciption of Metal Sheet Laser Cutter

1. Entegre makine tasarımı: makinenin sol ve sağ tarafındaki sol ve sağ toplama çekmecesi, yerden tasarruf sağlar.

2. Işık yolu sistemi ve kontrol sisteminin kararlılığı ve güvenilirliği.

3. Fiber lazer 100000 saatten fazla yüksek ve kararlı bir işleve ve ömre sahiptir.

4. Kesme hızı mükemmel kesim kenarı ile 25m / dk'ya kadar olan kesme kalitesiyle daha yüksek kesme kalitesi ve verimi.

5. Yüksek performanslı redüktör, dişli ve raf; Japon rehber ve vidalı mil.

Metal Sheet Laser Cutter Advantages

(1) Fiber laser cutting machine is for metal precise cutting powered by fiber laser technology. The quality fiber laser beam results in faster cutting speeds and higher quality cuts compared to other cutting solutions. The key advantage of a fiber laser is its short beam wavelength (1,064nm). The wavelength, which is ten times lower than that of C02 laser, generates high absorption into metals. This makes the fiber laser become a perfect tool for cutting metal sheets of stainless steel, carbon steel, mild steel, aluminum, brass, etc.

(2) The efficiency of a fiber laser far exceeds traditional YAG or CO2 laser. The fiber laser beam is capable of cutting reflective metals with much less energy as the laser is absorbed into the metal being cut. The unit will consume little to no energy when not active.

(3) Another advantage of fiber laser is the use of highly reliable single emitter diodes with projected lifetimes greater than 100,000 hours of continuous or pulsed operation.

(4) software allows for the capability to control power, modulation rate, pulse width and pulse shape giving the user full control of the lasers capabilities.

Teknik özellikler

| Lazer dalga boyu | 1080nm |

| Kesme kalınlığı | 0.2-16mm |

| Lazer çıkış gücü | 1000W |

| Maksimum işlem aralığı | 3000 * 1500mm |

| Makine sürüş modu | ithal dişli kutusu ve pinon tahriki |

| Y X. eksen konumlandırma hassasiyeti | ± 0.01mm |

| XY ekseni tekrar konumlandırma hassasiyeti | ± 0.01mm |

| Güç kaynağı modu | 380V / 50Hz |

| Maksimum kesme hızı | 45m / dakika |

| Minimum kesme çizgisi genişliği | 0.02mm |

| Soğutma modu | 3 P Su soğutma |

Aksesuarlar

Uygulama endüstrisi

Applied to the sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automotive, food machinery, textile machinery,engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, gifts, tooling, decoration, advertising , metal external processing,processing, and other kitchenware manufacturing and processing industries.

Uygulama malzemeleri

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate,copper and many kinds of metal materials cutting and so on.